What is a Brass Ball Valve

A brass ball valve is a type of valve made of brass material, which features a spherical ball inside its body that rotates to control the flow of fluid or gas passing through it. This type of valve is commonly used in plumbing systems, irrigation systems, and other applications where precise flow control is needed.

Brass is a popular material for brass ball valves due to its excellent durability, resistance to corrosion, and ability to withstand high temperatures and pressures. Brass ball valves are available in a variety of sizes, with threaded or flanged ends, and can be operated manually or with an actuator.

One advantage of a brass ball valve is its ability to completely shut off the flow of fluid or gas, which makes it ideal for applications where a tight seal is required. They are also relatively easy to install and maintain, making them a popular choice for many industries.

In summary, a brass ball valve is a reliable and durable brass Valve material that is widely used in a variety of applications due to its excellent performance and ease of use.

Advantages of using a brass ball valve

Brass valves are a popular choice for a variety of industries due to their many advantages. Some of the key advantages of using a brass ball valve are:

- Durability: Brass is a durable material that can withstand high temperatures and pressures, making brass ball valves a reliable option for many applications.

- Corrosion-resistant: Brass is also resistant to corrosion, which means that brass ball valves can withstand exposure to water and other corrosive substances without deteriorating over time.

- Easy to install: Brass ball valve is relatively easy to install and require minimal maintenance, which can save time and money in the long run.

- Tight sealing: Brass ball valve provide a tight seal when fully closed, which prevents any fluid or gas from leaking through the valve.

- Versatility: Brass ball valves are available in a variety of sizes and configurations, making them suitable for a wide range of applications, including plumbing systems, irrigation systems, and industrial applications.

- Cost-effective: Compared to other types of valves, brass ball valves are typically more cost-effective, making them an attractive option for budget-conscious customers.

In summary, brass ball valves offer a range of advantages that make them a popular choice for many applications. Their durability, corrosion resistance, ease of installation, tight sealing, versatility, and cost-effectiveness make them a reliable and cost-effective choice for customers across many industries.

What Is a PVC Ball Valve?

A PVC ball valve is a type of valve made from polyvinyl chloride (PVC) material, which features a spherical ball inside its body that rotates to control the flow of fluid or gas passing through it. PVC ball valves are commonly used in a variety of applications, including plumbing systems, irrigation systems, and industrial processes.

PVC is a popular material for valves due to its excellent resistance to corrosion, chemicals, and high temperatures. PVC ball valves are available in a variety of sizes, with threaded or flanged ends, and can be operated manually or with an actuator.

One advantage of a PVC ball valve is its affordability, making it a cost-effective option for many customers. PVC ball valves are also easy to install and maintain, making them a popular choice for a variety of applications.

PVC ball valves are often referred to as two-way valves, as they allow the flow of fluid or gas in two directions. They are also available in three-way configurations, which allow for more complex flow control applications.

In summary, a PVC ball valve is a reliable and cost-effective valve made from PVC material that is widely used in a variety of applications due to its excellent performance and ease of use.

Advantages Of using PVC Ball Valve

PVC ball valves offer a range of advantages that make them a popular choice for many applications. Some of the key advantages of using a PVC ball valve are:

- Chemical resistance: PVC resin is highly resistant to a wide range of chemicals, making PVC ball valves an ideal choice for chemical processing industries.

- Corrosion resistance: PVC ball valves are also resistant to corrosion, which makes them suitable for use in environments where corrosion can be a problem.

- Lightweight: PVC is a lightweight material, which makes PVC valves easy to handle and install.

- Cost-effective: PVC ball valves are often less expensive than other types of valves, making them an attractive option for customers on a budget.

- Easy to install: PVC ball valves are easy to install and require minimal maintenance, which can save time and money in the long run.

- Versatility: PVC valves are available in a variety of sizes and configurations, making them suitable for a wide range of applications, including plumbing systems, irrigation systems, and industrial applications.

In summary, PVC ball valves offer a range of advantages that make them a reliable and cost-effective option for customers across many industries. Their chemical and corrosion resistance, lightweight construction, affordability, ease of installation, and versatility make them a popular choice for many applications.

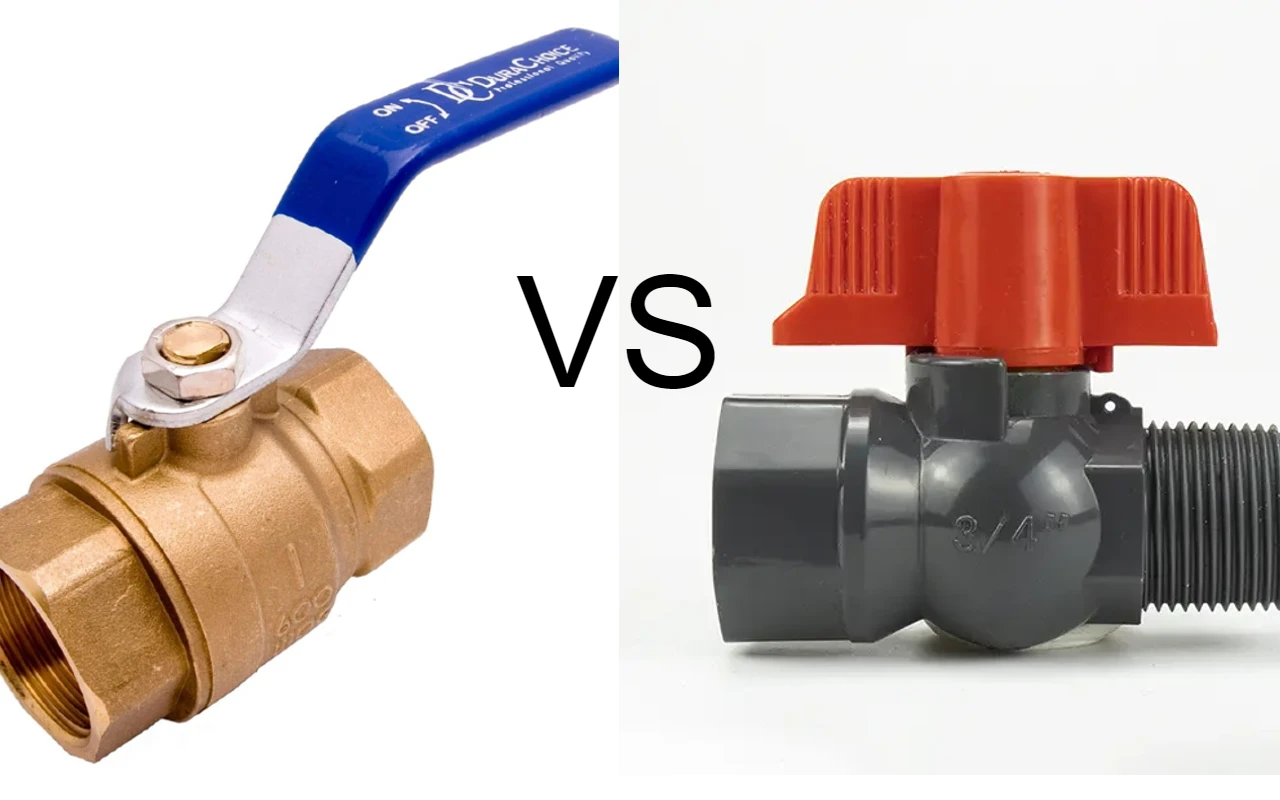

Major Differences between Brass & PVC Ball Valve

PVC ball valves and brass ball valves are two popular types of valves that are used in a variety of applications. While both types of valves are designed to control the flow of fluid or gas, there are several key differences between PVC and brass ball valves.

- Material: One of the main differences between PVC and brass ball valves is the material they are made from. PVC ball valves are made from polyvinyl chloride (PVC) resin, while brass ball valves are made from brass. PVC valve is a lightweight and cost-effective material, while brass is a more durable and corrosion-resistant material.

- Corrosion resistance: Brass ball valves are highly corrosion-resistant, making them suitable for use in environments where corrosion can be a problem. PVC ball valves, on the other hand, are not as corrosion-resistant as brass ball valves, which means that they may not be suitable for use in harsh or corrosive environments.

- Temperature resistance: Brass ball valves can withstand high temperatures and pressures, making them suitable for use in a wide range of applications. PVC ball valves, on the other hand, may not be suitable for use in high-temperature applications, as they can become brittle and prone to cracking.

- Strength: Brass is a stronger material than PVC, which means that brass ball valves are less likely to crack or break under pressure. PVC ball valves, on the other hand, may not be as strong as brass ball valves, which means that they may be more prone to failure under pressure.

- Cost: PVC ball valves are typically less expensive than brass ball valves, which makes them an attractive option for customers on a budget. Brass ball valves, on the other hand, are more expensive than PVC ball valves, but they offer better performance and durability in some applications.

- Installation: Both PVC valves and brass ball valves are relatively easy to install, but PVC ball valves are typically easier to handle and install than brass ball valves. PVC pipe valves are often used in residential and commercial plumbing systems because they are lightweight, easy to install, and cost-effective.

In summary, both PVC valves and brass ball valves offer advantages and disadvantages depending on the specific application. PVC ball valves are lightweight, cost-effective, and easy to install, but they may not be suitable for high-temperature or corrosive environments. Brass ball valves are more expensive, but they offer better durability, strength, and corrosion resistance than PVC ball valves. Ultimately, the choice between PVC Ball Valves and brass ball valves will depend on the specific needs of the application.

Factors to consider when choosing between brass and PVC ball valves

When choosing between PVC and brass ball valves, there are several factors to consider. These include the application, the operating conditions, and the budget.

- Application: The first factor to consider when choosing between PVC and brass ball valves is the application. PVC ball valves are suitable for use in applications where low pressure and temperature conditions are present, such as residential plumbing systems. Brass ball valves are suitable for use in applications where higher pressure and temperature conditions are present, such as industrial and commercial plumbing systems.

- Operating conditions: The second factor to consider is the operating conditions. PVC ball valves are not as corrosion-resistant as brass ball valves, which means that they may not be suitable for use in corrosive environments. Brass ball valves are highly corrosion-resistant, making them suitable for use in harsh or corrosive environments.

- Budget: The third factor to consider is the budget. PVC ball valves are typically less expensive than brass ball valves, which makes them an attractive option for customers on a budget. Brass ball valves are more expensive than PVC ball valves, but they offer better performance and durability in some applications.

In summary, when choosing between PVC and brass ball valves, it is important to consider the application, the operating conditions, and the budget. By considering these factors, customers can choose the type of valve that will offer the best performance and value for their specific needs.

How To Choose: Brass Vs. PVC Ball Valve

Choosing between a brass ball valve and a PVC ball valve requires careful consideration of several factors. The first factor to consider is the application. PVC ball valves are ideal for use in low-pressure and low-temperature applications such as residential plumbing systems, while brass ball valves are better suited for high-pressure and high-temperature applications such as industrial and commercial plumbing systems.

The next factor to consider is the operating conditions. PVC ball valves may not be suitable for use in corrosive environments, while brass ball valves are highly corrosion-resistant and can withstand harsh conditions. It is important to choose a valve that can withstand the operating conditions it will be exposed to.

Another factor to consider is the budget. PVC ball valves are typically less expensive than brass ball valves, but brass ball valves offer better performance and durability in some applications. It is important to balance the budget with the specific needs of the application.

Ultimately, the choice between a brass ball valve and a PVC ball valve will depend on the specific needs of the application. By carefully considering the application, operating conditions, and budget, customers can choose the valve that will offer the best performance and value for their needs.

FAQs

Is PVC or Brass Check Valve Better?

When it comes to choosing between a PVC ball valve and a brass ball valve, it ultimately depends on the specific needs of the application. In terms of check valves, both PVC and brass options are available. Brass check valves are generally more durable and corrosion-resistant, making them suitable for use in harsh or corrosive environments. PVC check valves are typically less expensive and lighter in weight, making them a popular choice for residential plumbing systems. Ultimately, the choice between a PVC or brass check valve will depend on the specific needs of the application.

How Long Does a PVC Ball Valve Last?

The lifespan of a PVC ball valve can vary depending on factors such as the quality of the valve, the operating conditions, and the frequency of use. Generally, a well-maintained PVC ball valve can last anywhere from 5 to 10 years. However, exposure to harsh chemicals, extreme temperatures, or frequent use can shorten the lifespan of the valve. It is important to inspect PVC ball valves regularly and replace them as needed to ensure the proper functioning of the plumbing system.

Can a PVC Ball Valve Be Repaired?

In most cases, PVC ball valves cannot be repaired and must be replaced. PVC valves are typically manufactured as a single unit, with the valve and housing combined. If a valve becomes damaged or starts to leak, it is usually more cost-effective to replace the entire valve rather than attempting to repair it. However, some minor repairs, such as replacing a broken handle, may be possible. It is important to consult the manufacturer’s instructions or seek the advice of a professional plumber before attempting any repairs on a PVC ball valve.

Are PVC Ball Valves Any Good?

PVC ball valves are a popular choice for many residential plumbing applications due to their affordability and ease of installation. They are also resistant to corrosion and chemical damage, making them suitable for use in many different environments. However, PVC ball valves may not be as durable as brass ball valves and may not be suitable for use in high-pressure or high-temperature applications. It is important to carefully consider the specific needs of the plumbing system before choosing a PVC ball valve.

Are Brass Valves Better Than Plastic?

Brass ball valves are generally considered to be more durable and corrosion-resistant than plastic valves. They are also able to withstand high-pressure and high-temperature conditions, making them suitable for use in industrial and commercial plumbing systems. Plastic valves, such as PVC ball valves, are typically less expensive and lighter in weight, making them a popular choice for residential plumbing systems. Ultimately, the choice between a brass valve and a plastic valve will depend on the specific needs of the application.

Leave a Reply